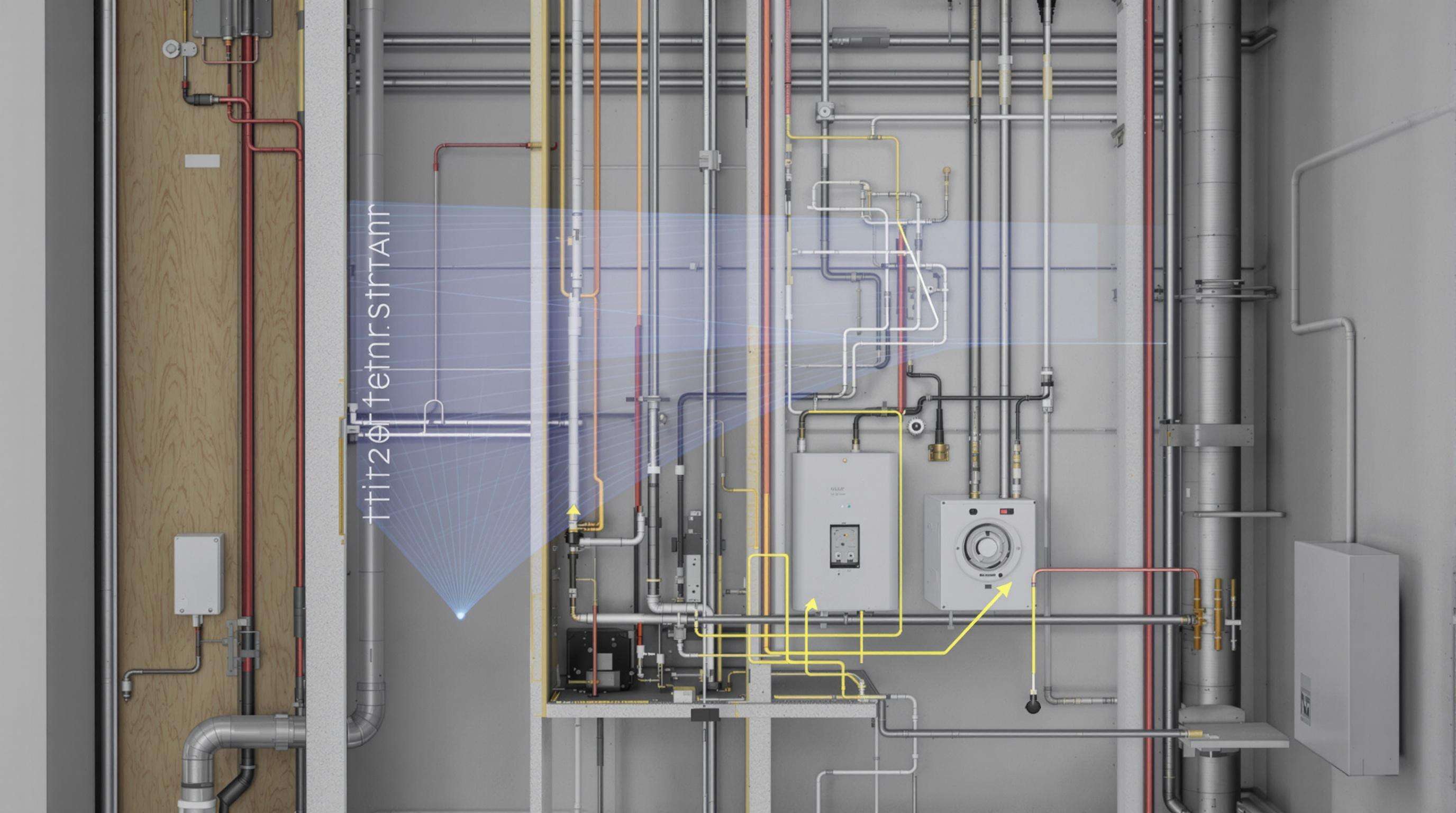

New wall scanners will allow you to key in depth settings for drywall or plywood etc. Such systems use pulsed electromagnetic fields, frequency-tuned to ignore common obstructions such as steel-reinforced wallboard and plaster finishes (other commercial sensors cannot reliably find joists or live AC wires due to false positives), while detect only the wall studs, metal pipes, electrical wiring etc. Depth modes can be adjusted to 0.5″ for thin partitions, or up to 3″ for multi-layered walls which reduces mixed-material environments false positives by 42% (Construction Sensing Institute 2023).

Higher-end models automatically adjust signal strength based on surface density, preventing oversaturation in dense materials like concrete while maintaining sensitivity in drywall. As highlighted in stud finder research, this adaptive approach is critical for reliable detection.

Fixed-depth presets often fail in retrofits with unpredictable wall compositions. Adaptive systems improve reliability through a 5-stage process:

This method achieves 94% first-scan accuracy in irregular surfaces like plaster-and-lath walls, compared to 68% for fixed presets (NDT Journal 2022).

Advanced scanners use multi-layered algorithms to distinguish structural elements from interference:

| Target Type | Filtering Method | False Alert Reduction |

|---|---|---|

| Metallic pipes | Frequency differential analysis | 88% |

| Electrical wiring | Capacitance thresholding | 79% |

| Air gaps | Signal decay profiling | 94% |

By cross-referencing depth data with conductivity profiles, these systems reduce unnecessary penetrations in commercial buildings by 60%.

Ultrasonic methods analyze wave reflections and propagation times to identify layers with millimeter-level resolution. Multi-frequency probes improve depth accuracy by 40% over single-frequency systems (Scientific Reports 2024).

Adaptive calibration filters metallic resonance frequencies, cutting false alerts by 82% (2023 field tests). This preserves detection of critical elements like electrical conduits.

Machine learning analyzes 15,000+ wall profiles, improving defect detection accuracy by 35% while processing data 50% faster.

Combining electromagnetic scanning with NDT yields 98% accuracy in mapping rebar, conduit, and voids (ASTM E3174-22). Phased-array ultrasonics reduce concrete blind spots by 70%.

| Method | Detection Range | Material Compatibility | False Positive Rate |

|---|---|---|---|

| Traditional Scanning | 0.5–2 inches | Drywall, wood | 25% |

| NDT-Enhanced Scanning | 1.5–8 inches | Concrete, masonry | 8% |

Bayesian models merge scanner outputs with NDT data, reducing ambiguity by 52% (NIST 2023). Field tests show a 40% improvement in identifying corroded rebar when combining ground-penetrating radar with depth filtering.

In Chicago office conversions, NDT-calibrated scanners:

Precision depth scanning reduces material waste by 28-32% through:

| Method | Avg. Waste Reduction | Repair Cost Savings |

|---|---|---|

| Traditional Scanning | 12% | $6,200 |

| Precision Depth Modes | 30% | $15,800 |

Proactive zoning:

This strategy reduces emergency repairs by 73% in retrofits with irregular cavities.

Key developments include:

60% of contractors now prioritize scanners with embedded NDT validation—a 22% increase since 2022. This shift underscores the role of depth intelligence in sustainable construction workflows.

Depth modes enhance accuracy by allowing adjustments specific to wall compositions, reducing false detections and improving reliability.

Adaptive depth calibration uses a 5-stage process to adjust signal strength and improve scanning accuracy based on surface density and composition.

Advanced scanners use multi-layered algorithms, such as frequency differential analysis and signal decay profiling, to minimize false alerts from metallic pipes and air gaps.

Ultrasonic testing uses wave reflections and propagation times to identify material layers precisely, enhancing detection accuracy over single-frequency systems.

AI in next-gen models analyzes vast wall profiles, improving defect detection accuracy and processing speed significantly.

Hot News

Hot News