Product Introduction

The digital level from Fuzhou Yu Xin Electronic Co., Ltd. is a precision instrument engineered to deliver accurate measurements in construction, surveying, and industrial applications. Designed with technical excellence, it integrates advanced sensors and user-centric features to meet the rigorous demands of professional projects. Whether used on construction sites, in manufacturing facilities, or during land surveys, this digital level ensures reliable data collection, making it an indispensable tool for technicians and engineers who prioritize precision. Its robust design and intelligent functions set it apart as a trusted solution for maintaining measurement integrity across diverse working environments.

Product Features

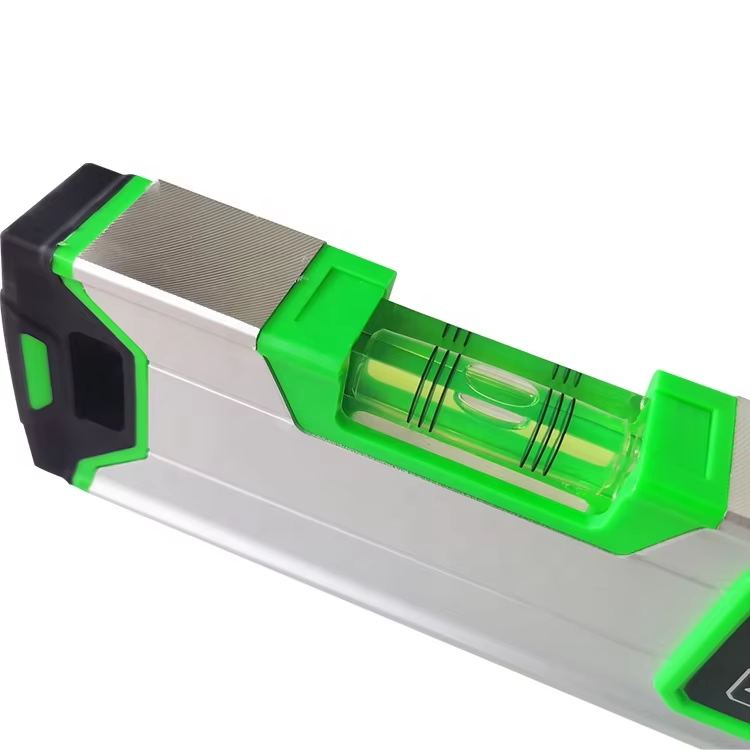

Sturdy and Durable

Our digital level boasts a rugged construction that withstands harsh job site conditions. Crafted from high-grade aluminum alloy and reinforced plastics, it resists impacts, dust, and moisture—critical for longevity in construction zones or outdoor settings. The casing protects internal components, including sensitive sensors, from vibrations and accidental drops, ensuring consistent performance over time. This durability minimizes downtime due to damage, making it a cost-effective choice for B2B clients who rely on equipment to endure daily wear and tear in demanding environments.

Data Storage and Output

Equipped with ample internal memory, the digital level can store thousands of measurement records, eliminating the need for manual note-taking. It supports USB and Bluetooth connectivity, allowing seamless data transfer to computers, tablets, or project management software. This feature streamlines workflow: technicians can quickly export readings for analysis, share data with teams in real time, or archive records for compliance. For large-scale projects requiring traceability, this capability ensures measurement data remains organized and accessible, reducing errors associated with manual data entry.

Automatic Calibration

A standout feature is its automatic calibration function, which simplifies maintenance while preserving accuracy. With a single button press, the device initiates self-calibration using internal reference points, adjusting sensor offsets to correct for environmental factors like temperature changes. This eliminates the need for complex manual procedures, making calibration accessible even to less experienced users. For professionals working in remote locations, automatic calibration ensures the digital level remains precise without relying on external tools or specialized expertise.

Tools and Materials Needed for Calibrating a Digital Level

Calibrating a digital level requires specific tools and materials to ensure accuracy. Here’s what you’ll need:

- Calibration Stand or Reference Surface: A precision-machined, flat platform (typically made of granite or stabilized steel) with certified levelness. This provides a baseline for verifying the digital level’s readings.

- Spirit Level (Master Calibrator): A high-precision optical spirit level with traceable calibration certificates, used to cross-verify the reference surface’s flatness before starting.

- Cleaning Kit: Microfiber cloths and isopropyl alcohol to clean the digital level’s base and the reference surface, removing dust or debris that could skew measurements.

- Temperature-Stable Environment: A room or enclosure with minimal temperature fluctuations (ideally 20–25°C/68–77°F) to prevent sensor drift during calibration.

- Calibration Software (Optional): For advanced users, proprietary software (provided with our digital level) can connect via USB to log calibration data and generate compliance reports.

- Protective Case: To store the digital level and tools safely between uses, preventing damage that could affect calibration integrity.

How to Calibrate a Digital Level for Optimal Accuracy?

Calibrating a digital level is critical to maintaining measurement integrity. Here’s a step-by-step guide using the tools above:

- Prepare the Workspace: Set up the calibration stand in a temperature-stable area. Use the master spirit level to confirm the surface is level within ±0.001°. Clean the stand and digital level base with the microfiber cloth and alcohol.

- Power On and Initialize: Turn on the digital level and let it warm up for 10–15 minutes to stabilize internal components. Navigate to the settings menu and select “Calibration Mode.”

- Run Automatic Calibration: Place the digital level on the reference surface, ensuring full contact. Press the “Auto-Calibrate” button—the device will rotate its internal sensors, compare readings to built-in benchmarks, and adjust offsets automatically. The screen will display “Calibration Complete” when finished.

- Verify with Manual Checks: Flip the digital level 180° on the same surface and take a reading. The difference between original and reversed measurements should be within ±0.02°. If not, repeat the calibration or use the master spirit level to troubleshoot.

- Document Results: Record calibration date, ambient temperature, and verification readings. For compliance-driven industries, export data via USB to the calibration software for 存档.

FAQs:

- Why calibrate regularly? Sensors drift over time due to usage and environmental factors, leading to inaccuracies.

- What if calibration fails? Clean the device’s base, check for damage, and retry. Contact support if issues persist.

Product Production Process

The manufacturing of our digital level adheres to strict quality protocols, ensuring each unit meets precision standards:

- Component Sourcing: Critical parts—including high-precision tilt sensors, durable casings, and long-life batteries—are sourced from certified suppliers with a track record in aerospace or industrial-grade components.

- Assembly: Skilled technicians assemble the device in a climate-controlled facility, minimizing dust and temperature interference. Sensors are mounted with micron-level precision to ensure alignment, a key factor in calibration reliability.

- Software Integration: Proprietary firmware is installed to manage automatic calibration algorithms, data storage, and connectivity features. Each unit undergoes software testing to verify response times and calculation accuracy.

- Testing: Post-assembly, every digital level undergoes rigorous calibration checks using laser-aligned reference surfaces. It is exposed to temperature cycles and vibration tests to simulate field conditions, ensuring durability and consistent performance.

- Certification: Units that pass all tests receive a calibration certificate, confirming compliance with ISO 9001 and industry standards. This documentation guarantees traceability for B2B clients requiring audit-ready equipment.

Proper calibration, supported by the right tools and our digital level’s advanced features, ensures uncompromising accuracy. For B2B clients seeking reliable measurement solutions, Fuzhou Yu Xin Electronic Co., Ltd.’s digital level combines durability, smart functionality, and ease of calibration to elevate project quality. Ready to optimize your measurement processes? Leave your inquiry today—our team will assist with calibration guidance and product details tailored to your needs.

CH

CH