The Challenge of Job Site Efficiency

Construction and industrial projects often face one common challenge: inefficiency caused by inaccurate measurements and repeated rework. Even small errors in leveling walls, floors, or machinery can lead to wasted materials, extended project timelines, and increased labor costs. Traditional bubble levels, while reliable in certain situations, depend heavily on human judgment and are prone to misreading, especially in large-scale or complex projects.

This is where a digital level becomes a game-changer. By providing precise, repeatable, and easily readable measurements, digital levels help professionals save time, minimize errors, and enhance overall job site efficiency. For B2B buyers looking to reduce costs and improve workflow, investing in high-quality digital levels is an essential step.

Why Accuracy and Precision Matter on the Job Site

Accuracy and precision are critical in professional environments. In construction, a misaligned wall or uneven floor may require costly rework, not to mention potential delays that disrupt project schedules. In woodworking, minor deviations can compromise furniture assembly or cabinetry alignment. For industrial applications, improper measurements can result in machinery misalignment, affecting performance and safety.

High-performance digital levels provide readings accurate to fractions of a degree, reducing human error and ensuring consistency across multiple measurements. This level of precision allows project managers and contractors to plan effectively, avoid unnecessary corrections, and maintain quality standards throughout the project lifecycle. By minimizing errors, businesses not only save on material costs but also improve labor efficiency and client satisfaction.

Moreover, modern digital levels often come with calibration features, ensuring long-term reliability even under demanding job site conditions. This makes them an indispensable tool for professional teams that prioritize both precision and productivity.

Key Features of a High-Performance Digital Level

A top-tier digital level offers a range of features designed to improve workflow and reduce rework:

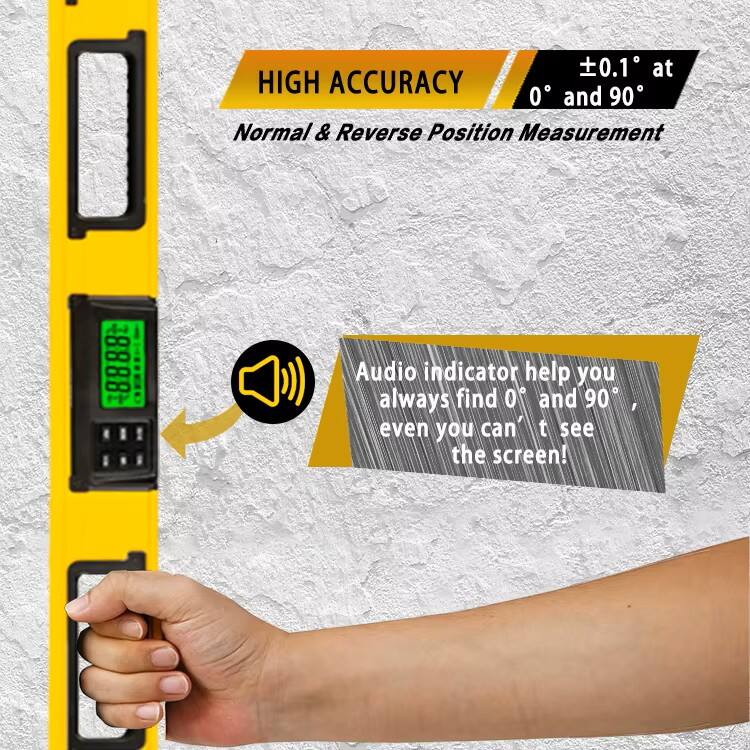

High-precision sensors and digital display: Instantly provide accurate readings, eliminating guesswork and misinterpretation.

Multiple measurement modes: Measure angles, slopes, and horizontal levels with a single device.

Enhanced usability: Backlit displays and audible alerts improve readability in dimly lit or noisy job site conditions.

Data storage and connectivity: Advanced models allow measurements to be saved and transferred via Bluetooth for easy documentation and team collaboration.

Durability and portability: Shockproof, dustproof, and water-resistant designs ensure reliable performance in demanding environments.

These features combine to make digital levels not just measurement tools but essential assets that enhance workflow, reduce mistakes, and support professional quality standards.

How Digital Levels Improve Job Site Efficiency

Digital levels contribute directly to job site efficiency in several ways:

Faster and more accurate measurements: Digital readouts remove the need for repeated checking and subjective interpretation of bubble vials.

Versatile measurements: Ability to measure angles, slopes, and horizontal levels in one tool reduces the need for multiple instruments, saving setup time.

Improved collaboration: Data storage and Bluetooth connectivity enable teams to share measurements instantly, ensuring everyone works from the same reference.

Reduced material waste and rework: Precise measurements prevent errors that could lead to costly rework or replacement of materials.

Consistent quality control: Standardized measurement procedures ensure repeatable accuracy across all project stages.

By incorporating digital levels, contractors and industrial teams can streamline workflow, complete tasks faster, and maintain high standards of workmanship without unnecessary delays.

Selecting the Right Digital Level for Your Projects

Choosing the right digital level depends on your project needs:

Precision requirements: Decide whether ±0.1° or ±0.05° accuracy is necessary.

Application type: Construction, woodworking, industrial measurement, or mixed-use projects may require different features.

Additional functions: Consider models with Bluetooth connectivity, data storage, backlit displays, and durable housings for rugged job site conditions.

Supplier considerations: Reliable B2B suppliers provide warranty, calibration support, and bulk order options to meet enterprise needs.

For B2B buyers, selecting a trusted supplier ensures long-term reliability, after-sales support, and access to high-quality professional digital levels that enhance overall productivity.

Real-World Applications and Case Studies

Construction: Contractors use digital levels for wall alignment, flooring installation, and door or window frame leveling, reducing errors and project delays.

Woodworking & Furniture Installation: Accurate measurements ensure precise assembly of cabinets, furniture, and wood panels, eliminating alignment issues.

Industrial Measurement: Piping systems, machinery setups, and precision equipment installations benefit from digital levels’ consistent accuracy, improving operational efficiency.

DIY and Commercial Projects: Even for smaller-scale commercial renovations, digital levels prevent mistakes and reduce the need for repeated adjustments.

Case studies from B2B clients show measurable improvements: reduced rework by up to 40%, faster project completion, and enhanced workflow efficiency. These results demonstrate how investing in digital levels translates directly into cost savings and higher-quality outcomes.

FAQ for B2B Buyers

Q1: How accurate is a digital level compared to traditional tools?

Digital levels provide precision down to fractions of a degree, outperforming bubble levels that rely on human interpretation.

Q2: Can digital levels withstand job site conditions?

Premium models are designed to be shockproof, dustproof, and water-resistant for long-term durability.

Q3: Are digital levels suitable for both professional contractors and DIY projects?

Yes, models range from entry-level for DIY to high-precision versions for professional use.

Q4: Do digital levels support bulk orders and technical support?

Most B2B suppliers offer wholesale pricing, custom calibration, and dedicated technical assistance for enterprise clients.

High-performance digital levels are more than tools—they are investments in accuracy, efficiency, and reliability. By reducing errors, minimizing rework, and enabling consistent measurement practices, digital levels empower professional teams to complete projects on time and within budget.

Explore our range of digital levels today. Request a quote, download product specifications, or contact our sales team to find the ideal solution for your business and elevate your job site efficiency.

CH

CH